Generation of foams and emulsions

The properties of foams and emulsions depend strongly on their structural properties, such as the bubble size and the bubble size distribution, and also the liquid fraction. Furthermore, the energy input during the generation of the foam or emulsion can play an important role in helping to bring the surface active agents to the interfaces. We therefore have a large range of different foam/emulsion generating devices in the lab, which allow us to generated foams or emulsions from nearly any kind of solution.

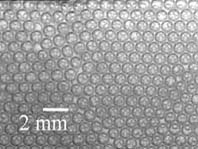

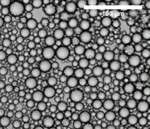

Monodisperse foam |  Polydisperse foam |

Polydisperse foams and emulsions

Shake it!

The simplest way to make a foam or an emulsion is by shaking: put the solution(s) into a bottle, close it and shake it violently. This may sound highly unscientific, but many serious foaming investigations are done this way.

|  |  |

| before | shake it! | after |

Blender and Ultra-Turrax

Foams and emulsions can easily be generated using strong shear flows, as they are present in a classic kitchen blender used to make whipped cream. A more scientific “blender” is the Ultra-Turrax (left image), which is used in particular to make emulsions with small droplet sizes of the order of 1 – 10 micrometers (right image).

|  |

Turbulent mixing

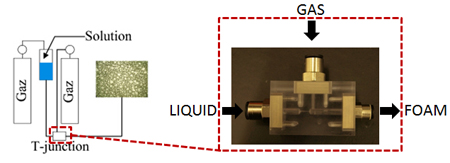

In the turbulent mixing device (developed by A. Saint-Jalmes), a gas and the foaming fluid are injected at high flow-rates into a T-junction with a special design. The gas joins the liquid after it has been accelerated by passing through a constriction. The sudden pressure drop behind the constriction helps to integrate the gas and to create a turbulent flow which breaks up bubbles and therefore creates a very fine, polydisperse foam with bubble sizes of the order of 100 micrometers. The liquid fraction of the foam can be varied by varying the ratio of the gas and liquid flow rate.

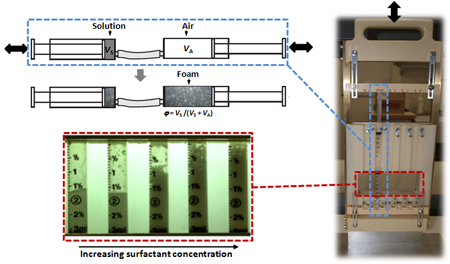

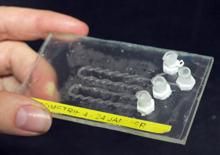

Parallel double syringes

The “double-syringe technique” is a particularly convenient method to generate polydisperse foams with small bubbles of well-controlled liquid fraction. The desired liquid and gas volume are each filled into a syringe. Both syringes are then connected by a small tube. To generate the foam, both pistons are pushed rapidly back and forth, such that the liquid and the gas are simultaneously pushed through the connecting tube. Bubble sizes are typically of the order of a few tens of micrometers, i.e. small. In order to compare different foaming solutions in one run, we have built a device which allows us to push/pull 5 double syringes in parallel. The device, with some typical resulting foams for increasing surfactant concentration are shown in the figure.

Extrusion-type foaming

For this type of foaming one puts the solution under high pressure (10-15 bar) using a gas which is easily soluble in the foaming solution. This is typically carbon dioxide (CO2). Under this high pressure, much of the gas is dissolved in the solution, which is stirred using a magnetic stirrer to speed up and to homogenize the dissolution process. In order to create the foam, the solution is released from the pressurized container. Upon the sudden pressure drop the dissolved gas comes out of solution and creates bubbles via a classical nucleation and growth process. The final bubble size and liquid fraction depend on the solubility of the gas and the pressure conditions.

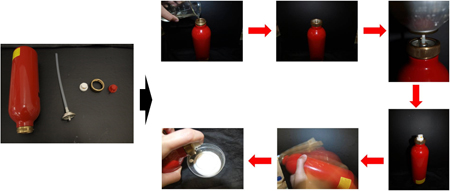

Shaving foam

In order to make shaving-type foams, one mixes the foaming solution with a mixture of butane/propane in a special bottle which allows to keep the mixture at a sufficiently high pressure so that the butane/propane mixture is in a liquid state. Shaking this mixture creates an emulsion (drops of butane/propane inside the foaming solution) inside the bottle. When releasing this mixture through a special valve on the head of the bottle, this emulsion becomes even finer. After release, the atmospheric pressure is too low to maintain the butane/propane mixture in the liquid state. It become gaseous and creates a lot of small bubbles in the foaming solution. Tuning the vapor pressure of the butane/propane mixture and its concentration in the foaming solution, one can control the final bubble size and liquid fraction of the foam. Bubble sizes are typically 10-100 micrometers.

Sonification

Micrometric bubbles and emulsion droplets can be generated using a sonicator, i.e. the energy coming from ultrasonic waves.

Monodisperse foams and emulsions

Bubble bubble

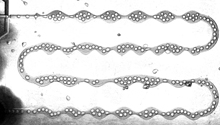

Milli- and mircofluidic flow techniques

Principle of generation, typical properties, link to site of channel production

|  |