The configuration and geometry of chemical reactors underpin the accuracy of performance evaluation for photocatalytic materials. Researchers have developed a novel automated photoreactor for H2 production. A photonic profile methodology was implemented to obtain the local light absorption, allowing to evaluate directly the quantum yield of the tested catalysts.

H2 is one of the most attractive solar fuel due to its high mass-energy content, which is up to three times higher than conventional fossil fuels, when used in direct combustion. Up to now, the scaling-up of photocatalytic H2 production has not reached a sufficient technological readiness level due to a dual bottleneck: (A) efficient, abundant, recyclable, and low-cost catalysts and (B) a scalable, reproducible, and easy to handle reactor with a homogeneous photonic/heat/mass profile. Therefore, the rational design of advanced photocatalytic systems has been the center of attention for several decades. Meanwhile, a lack of accurate photonic, mass, and heat transport profiles for photochemical reactors makes it difficult to standardize, scale up, and compare experiments.

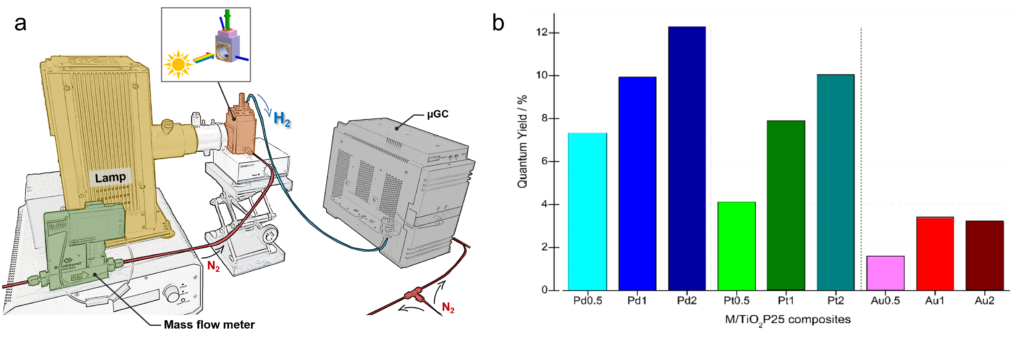

A multidisciplinary team led by researchers from Laboratoire de Physique des Solides, together with colleagues from Rutherford Appleton Laboratory, Universities of Granada, Camerino, Strasbourg and Southampton, have designed a compact photoreactor (Figure a) for automated H2 evolution reaction in the presence of a sacrificial agent with frontal irradiation. Benchmark TiO2/Schottky junctions, using Pd, Pt, or Au nanoparticles, were synthesized, and characterized before testing their performance to validate the operation of the reactor. A methodology was implemented to determine the local photonic absorption profiles, which allows extracting the local quantum yield for the selected materials. This work has been published in Chemical Engineering Journal.

A multiscale approach was applied to determine the distinctive surface and bulk properties to build structure–function correlations. Interestingly, (Pd, Pt, Au)/TiO2 Schottky junctions exhibit higher linear H2 production rates and quantum yields (Figure b), except for Au/TiO2 catalysts. This intriguing result has open up an in-depth analysis by energy electron loss spectroscopy, providing insightful information about the modification of the Au plasmon mode at the TiO2 interface. Overall, the H2 production capabilities in this work are significantly higher than currently established systems, putting into evidence that the geometry and reactor configuration could potentially be the benchmark to foster further progress in process and chemical engineering.

Reference

A compact photoreactor for automated H2 photoproduction: Revisiting the (Pd, Pt, Au)/TiO2 (P25) Schottky junctions

P. Jimenéz-Calvo, M. Muñoz-Batista, M. Issacs, V. Ramnnarain, M. A. Muñoz-Marquez, X. Li, D. Ihiawakrim, G. Teobaldi, M. Kociak, E. Paineau

Chemical Engineering Journal, 2023, 459, 141594

doi: 10.1016/j.cej.2023.141514

Available on ChemRxiv

CNRS Institut de Physique highlight

Contacts

Pablo Jimenéz-Calvo

Erwan Paineau